Introduction

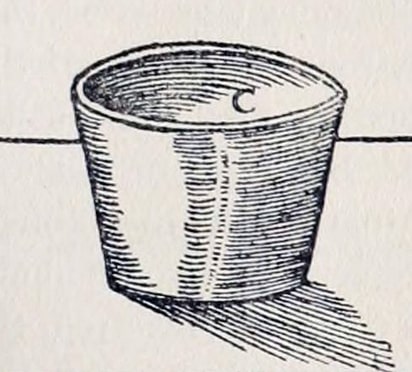

The word cupellation is used to either indicate a precise, analytical method of metal purity testing or a certain way of refining precious metals. The process takes advantage of the fact that precious metals don’t oxidize or chemically react while base metals do. Its name is derived from the small cup, a cupel, that is used to melt the metals. These cupels are made of a calcium or magnesium-rich substance to form a porous vessel. The basic principle of the method is as follows: A mix of lead, precious metals, and other base metals are heated in a cupel while a free flow of oxygen is allowed to reach the cup. The molten base metals react with the oxygen and are absorbed into the cupel as oxides while the precious metals remain at the bottom of the vessel. The role of lead is essential in the process as it acts as a catalyst for other base metals such as copper and tin to melt and oxidize. The lead oxide penetrates the cupel’s walls and forms a glassy coat which allows the other base metal oxides to pass into the cupel while blocking the precious metal.

Refining Precious Metals by Cupellation

Brooklyn Museum, Charles Edwin Wilbour Fund, 37.727E.Creative Commons-BY-NC.

Cupellation as a refining method was invented in the Early Bronze Age, probably in Mesopotamia and Anatolia, from where it spread to other parts of Eurasia. It enabled people to obtain pure silver from lead ores containing silver. Although silver is sometimes found as a native element its existence as such is rare, it usually occurs mixed with other minerals and lead. In order to refine it, these ores first have to be heated in a reducing atmosphere, which means that the flow of oxygen is eliminated or, at least, limited. The metals in the ore will melt to form a lead-silver alloy which can then be cupelled in order to extract the silver from the mix.

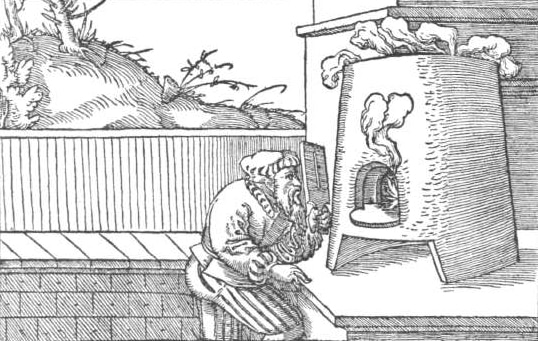

The Bronze Age refiners used a porous refractory clay to manufacture a cupel which would be filled with the metals and placed in a muffel furnace through which air is allowed to flow freely and heated to about 1000°C. The lead melts, oxidizes and penetrates the walls of the cupel and aids any other base metals present to do the same. The outcome was pure silver, sometimes mixed with gold if it was present in the original mineral mix.

Cupellation as a Purity Test

When cupellation started to be used as a way of assaying precious metal content is unclear. What we do know is that by the time Georgius Agricola wrote his De Re Metallica, which was first published in 1556, the practice was known and understood which indicates that it had already been in use for a long time.

When determining the gold content of an alloy is the objective, the testing process is as follows: A certain amount of gold is removed from the item. This removed material is weighed and its weight recorded. The material is then cupelled so that all base metals are removed. The remaining gold usually contains some silver which can be extracted by placing the metal in a solution of boiling nitric acid which dissolves the silver content. Pure gold remains as a black powder that can be filtered out and can be weighed again. Any weight loss represents the amount of added materials and therefore, the purity of the gold object can be determined. This method is accurate but has the disadvantage that a (small) portion of the gold has to be removed.

For More Information

- De Re Metallica pages 219-529, available online.