-

- Hancock Co., Chas. E.

Country City Providence RI

Symbol cartouche, frame, people, square, watch, woman

Shape cartouche, frame, square

Era c.1896, c.1915, c.1922

-

- Reich, M.A.

Country City Buffalo NY

Symbol cartouche, circle, frame, tool

Shape cartouche, circle, frame

Era c.1934 c.1950, c.1943

-

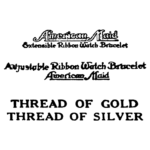

- Waite Thresher Co.

Country City Providence RI

Shape rectangle, star

Symbol rectangle, star

Era c.1915, c.1922, c.1934